CONVEYOR BELT SYSTEM AND WEIGHING SYSYEM

Conveyor belt system for the transport of waste knitted fabric from cutting machine to press complete with weighing system to take the weight of the material for a uniform and constant loading.

EXTRACTOR

It performs the extraction of the waste fabric from the basket automatically, for the successive handling to the cake opener.

Press

An automatic arm sprays water over the waste fabric that is deposited in a rotating basket. When the right quantity of waste fabric has been loaded, the press starts its cycle.

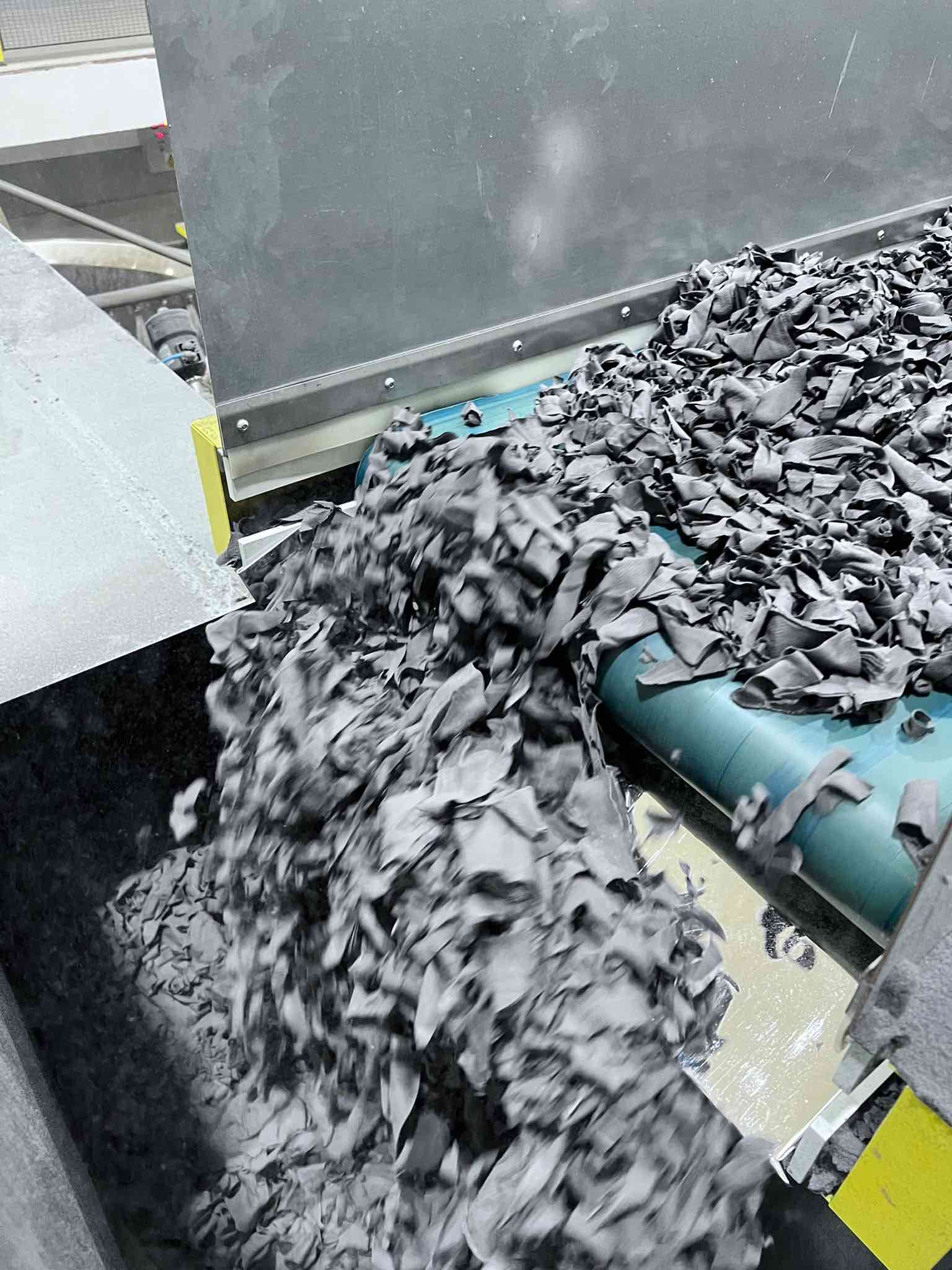

CAKE OPENER

It opens the waste fabric with pins conveyor and transfer it to the conveyor belt of the dryer. The uniform load of material in the conveyor belt of dryer is ensured by a volumetric dispenser.

HYDROEXTRACTABLE BASKETS

Made of special construction in AISI 316 L, they are suitable for the introduction both in the bleaching machine and in the hydroextractor.

LOW ENERGY HOT AIR DRYER

It has a modular design for easier addition of supplementary chambers at a later stage to increase the capacity. It has a special hot air circulation passing through the material and the stainless steel perforated conveyor belt from top to bottom. Equipped with filter to guarantee removal of impurities and dust and automatic system to control the speed of the belt, air temperature and final residual humidity of the material.

HIGH SPEED CENTRIFUGE

It ensures uniform extraction with minimal residual moisture, considerable reducing in drying times and recovery of energy by special inverter.