Hanks Equipment

Hanks Equipment

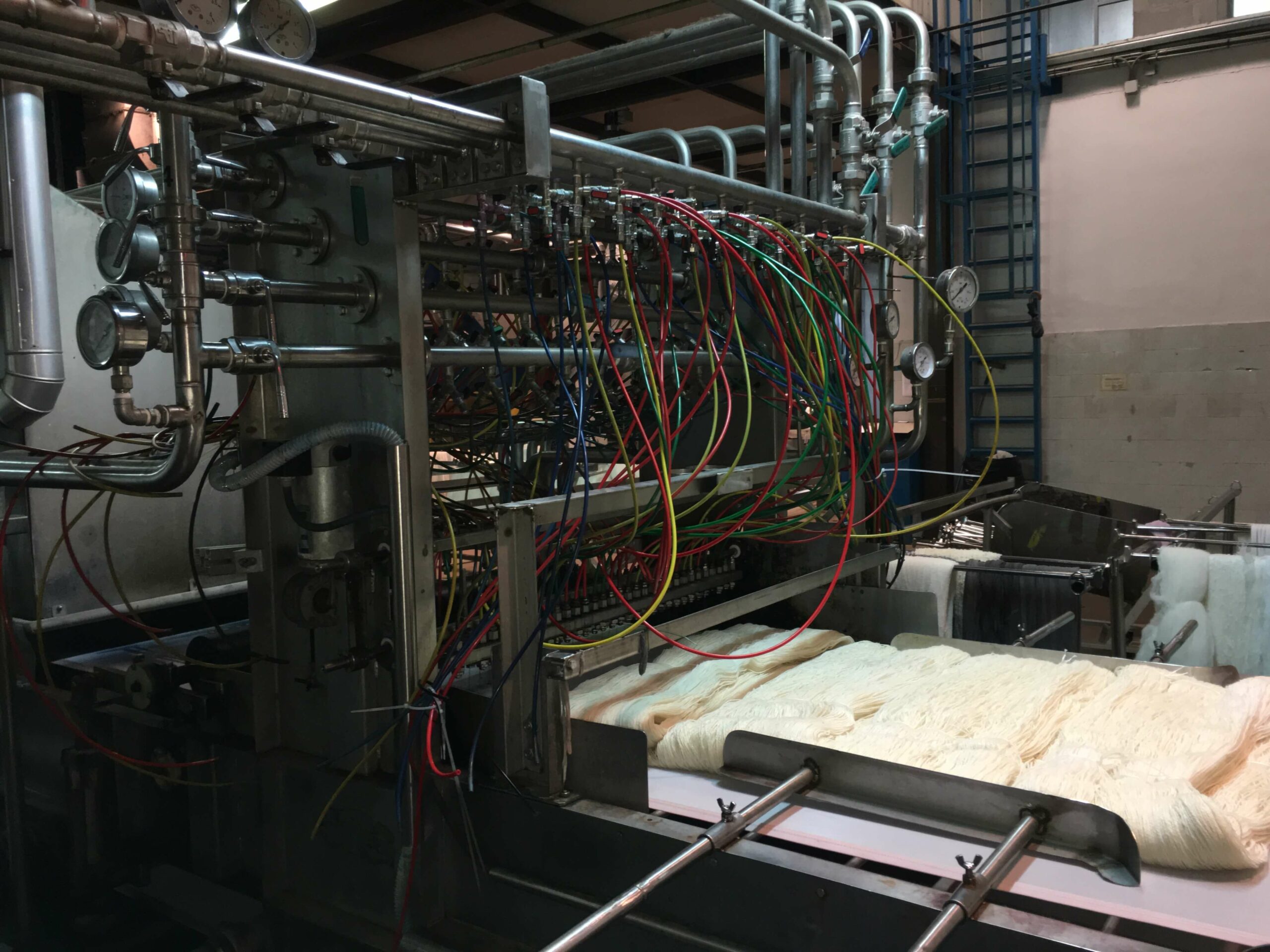

HANK DYEING MACHINE

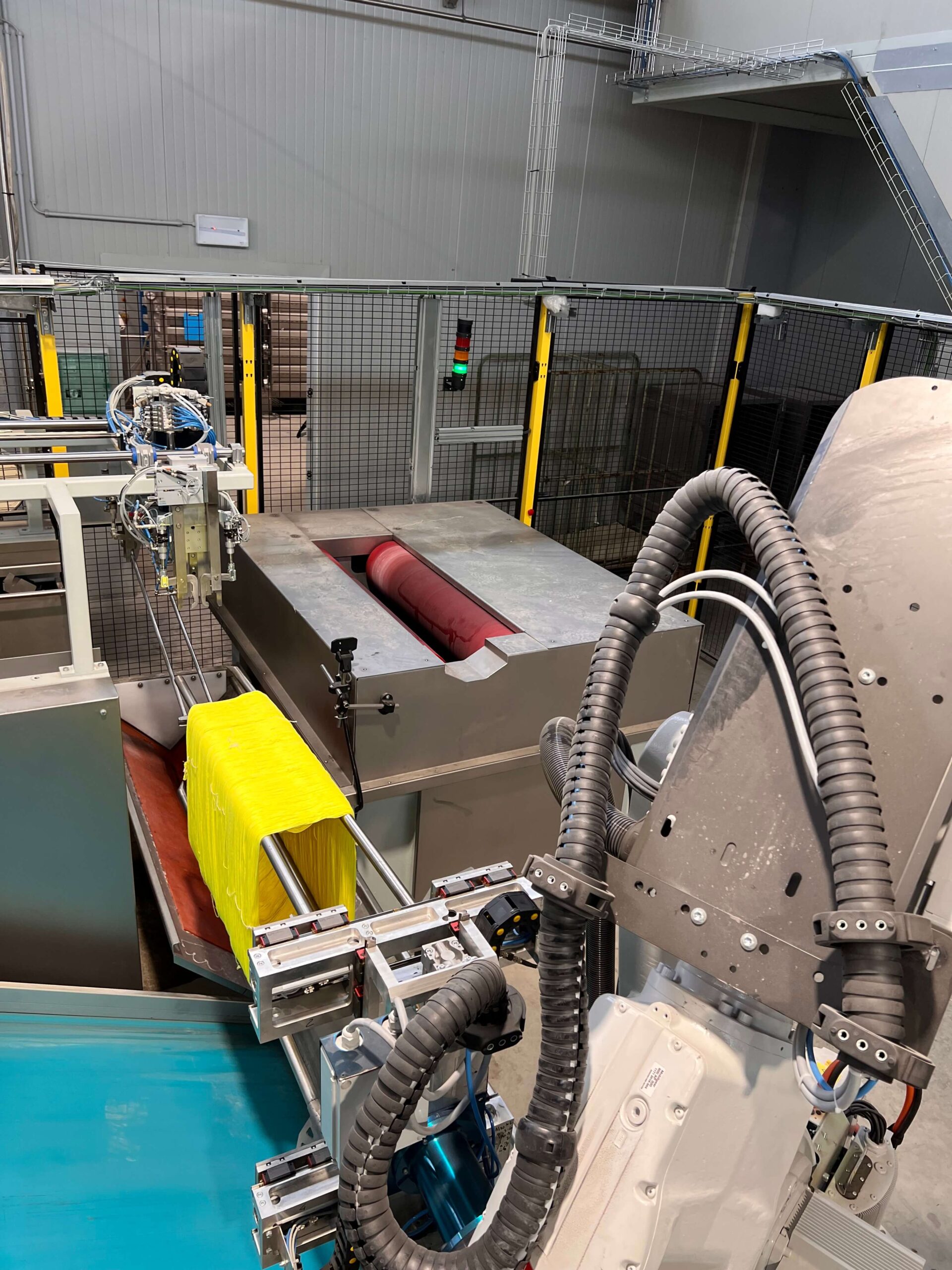

ROBOT

Once hanks are completely squeezed, the robot has the function to bring them out of the squeezer, enlarge them in their circumference and make their deposit easier over the rotation carrying arms of the dryer.

CENTRIFUGE

DRYER

The yarn is dried in the low-energy dryer at low temperature, ventilation inside the drying chamber is delicate and it is possible to set the final residual humidity of the yarn, thanks to the use of a special probe placed inside the chamber. Dryer can be at one or more floors, in order so save space in case of limited working area.

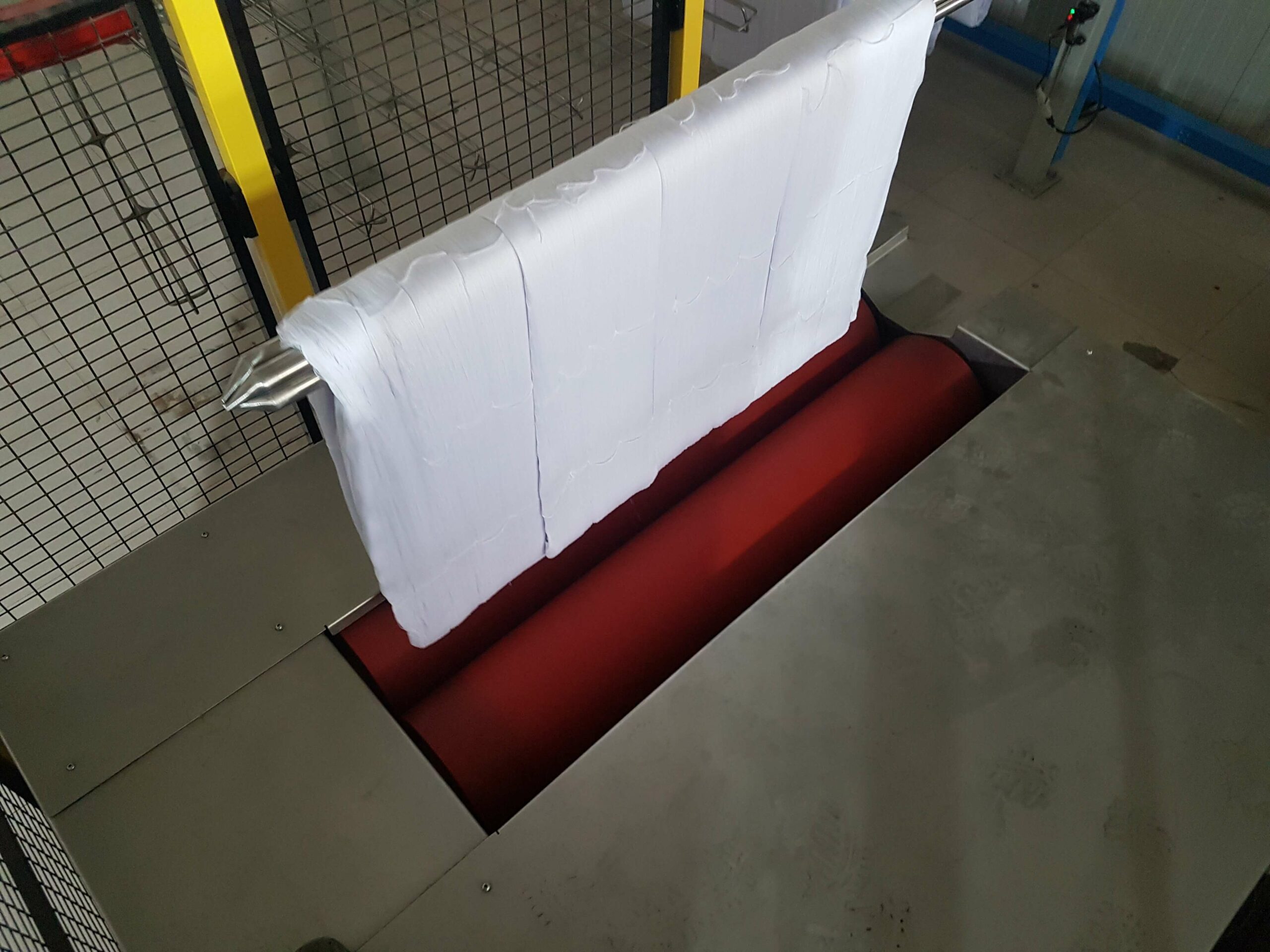

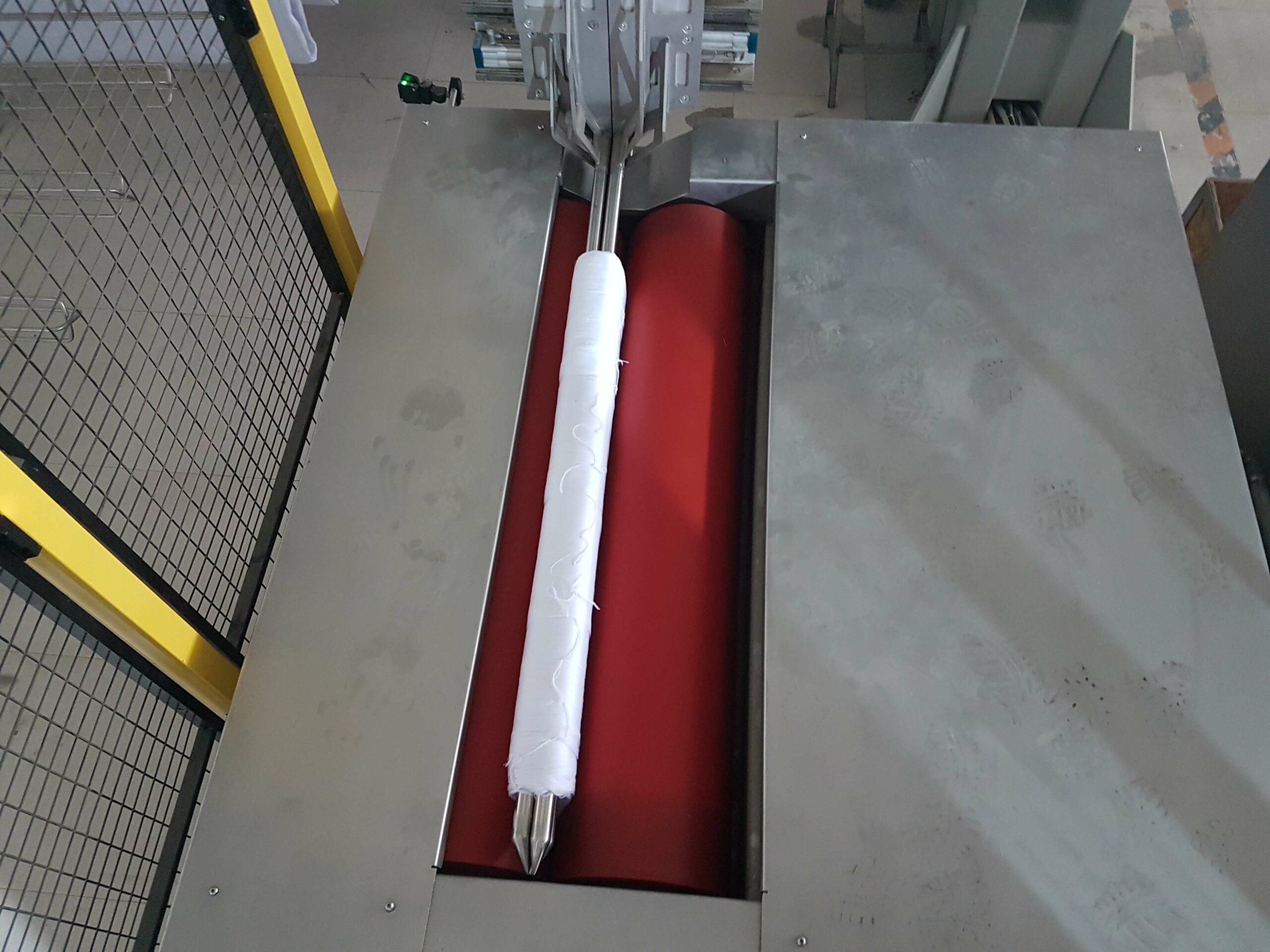

SQUEEZER

The automatic hanks squeezing system performed by Galvanin avoids every human touch on the yarn under process by assuring a remarkable save of work labour and preventing possible damages on the yarn due to human handling.

The material carrier, coming from the dyeing machine, can be transported close to the squeezer loading area where the operator directly laods the hanks, together with dyeing sticks, in a storing area which feeds automatically the squeezer.

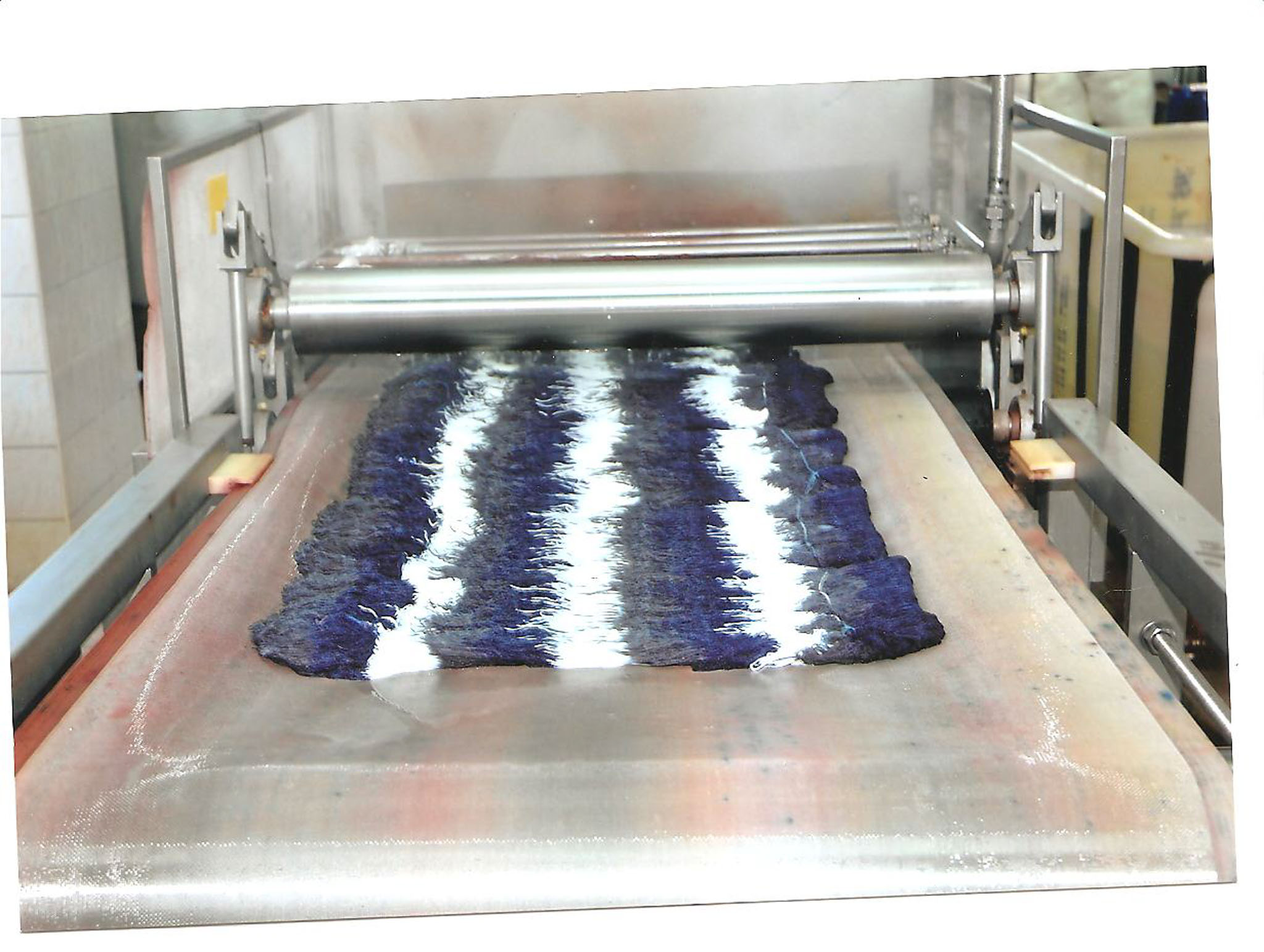

SPACE DYEING MACHINE

The Galvanin space dyeing machine is suitable for all the “Fancy Yarn” dyeing of hanks, fabrics and ready-to-wear garments. Completely built in stainless steel, it is provided with different nozzle and heating battery, anti dropping system, hot and cold washing system plus conditioner, special battery for high temperature for polyester dyeing and colour kitchen for sampling. The machine can be supply with a conveyor belt width of 1 or 2 meters, depending on the customer’s needs and there are three versions: 4, 6 or 8 colours.