Food Equipment

Food

Galvanin is a company certified to ASME “U” Stamp, PED, GOST (Ex Soviet Union) (with TIG, SMAW, SAW and PAW welding process), for the construction of pressure vessels. Leaders in the field of machinery for the textile sector, from several years has opened Food Division department in which, using highly qualified staff, is establishing itself as a manufacturer of machinery and equipment for food processing.

The line of our products for the dairy industry include:

- GTM 500 new automatic stretching machine, cooker for mozzarella cheese for pizza and spun dough cheeses in cycles of 500 kg., the cycle time is about 20 minutes. The machine, made completely in stainless steel AISI 316 L, allows to produce mozzarella in one only process starting from the various ingredients: liquid, in powder or frozen, saving several steps with consequent advantages in terms of working costs and at the same time it allows an increase in the quality of the worked product.

The line of our Food Division products includes:

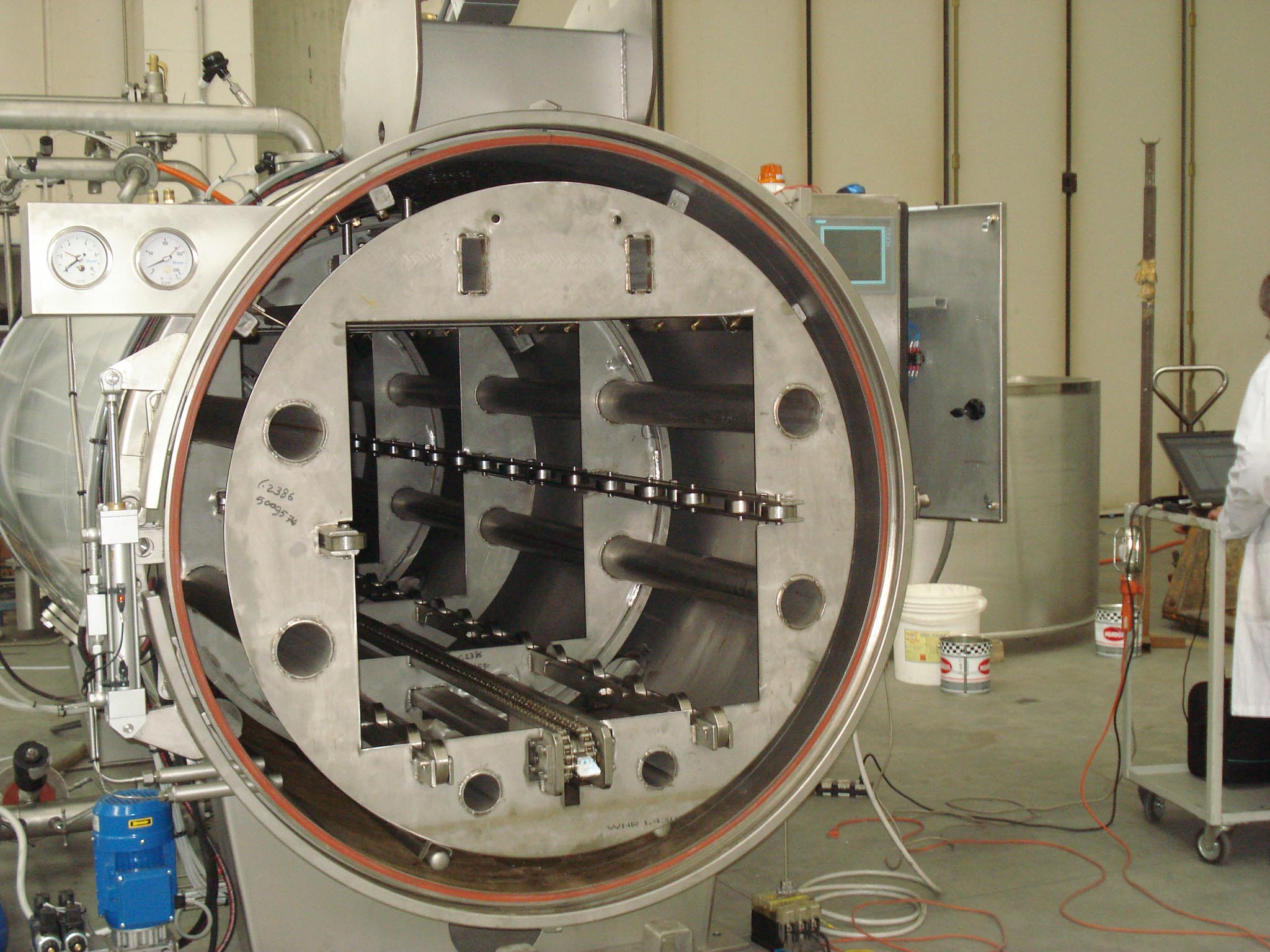

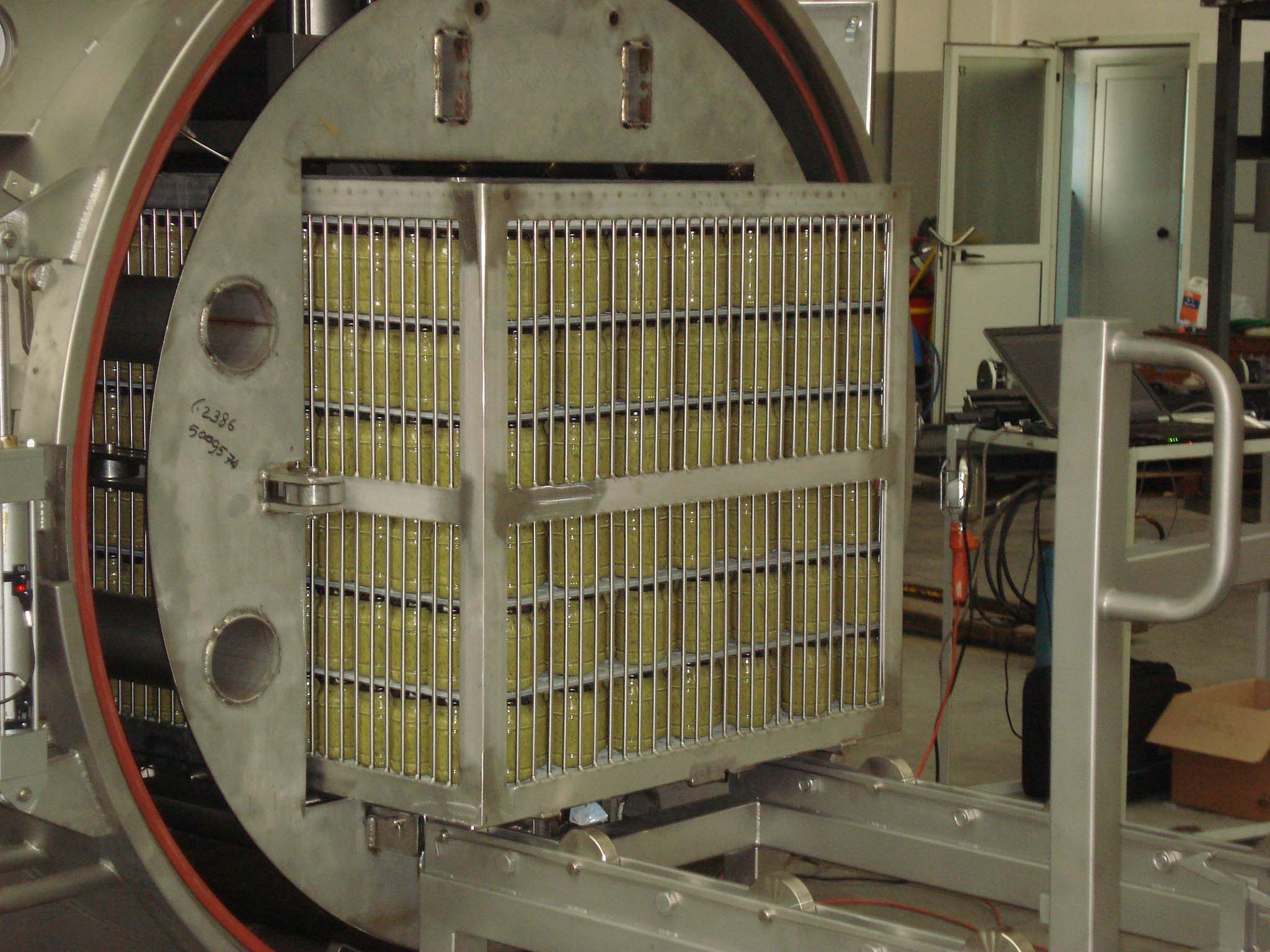

- Horizontal retort with full water immersion and bi-directional flow, retorts with direct steam, retorts with overheated rain waterfall and retorts with baskets rotation system, with diameters 1200, 1400 and 1700 mm and capacity from 1 to 6 baskets, suitable for both sterilization that the cooking of boxed products, or products in containers to tin plate or in glass jars, with the possibility of automatic, semiautomatic and manual shuttle systems for loading / unloading in retort, and loading / unloading systems for filling and discharging of the baskets;

- Plans for the storage and dosing of powder components and microingredients (such as salts, spices, acids, amides, pectins, etc..) with the possibility of mixing, dissolving and delivery of these to plant of use, ideal for the production of jams and preserves that cured meat and dairy industries;

- Defrost Units – mixers from 1.000 to 3.000 liters with heated serpentine for the preparation of fruit and vegetables with the possibility of tilting systems for trolleys load from 200 to 600 kg;

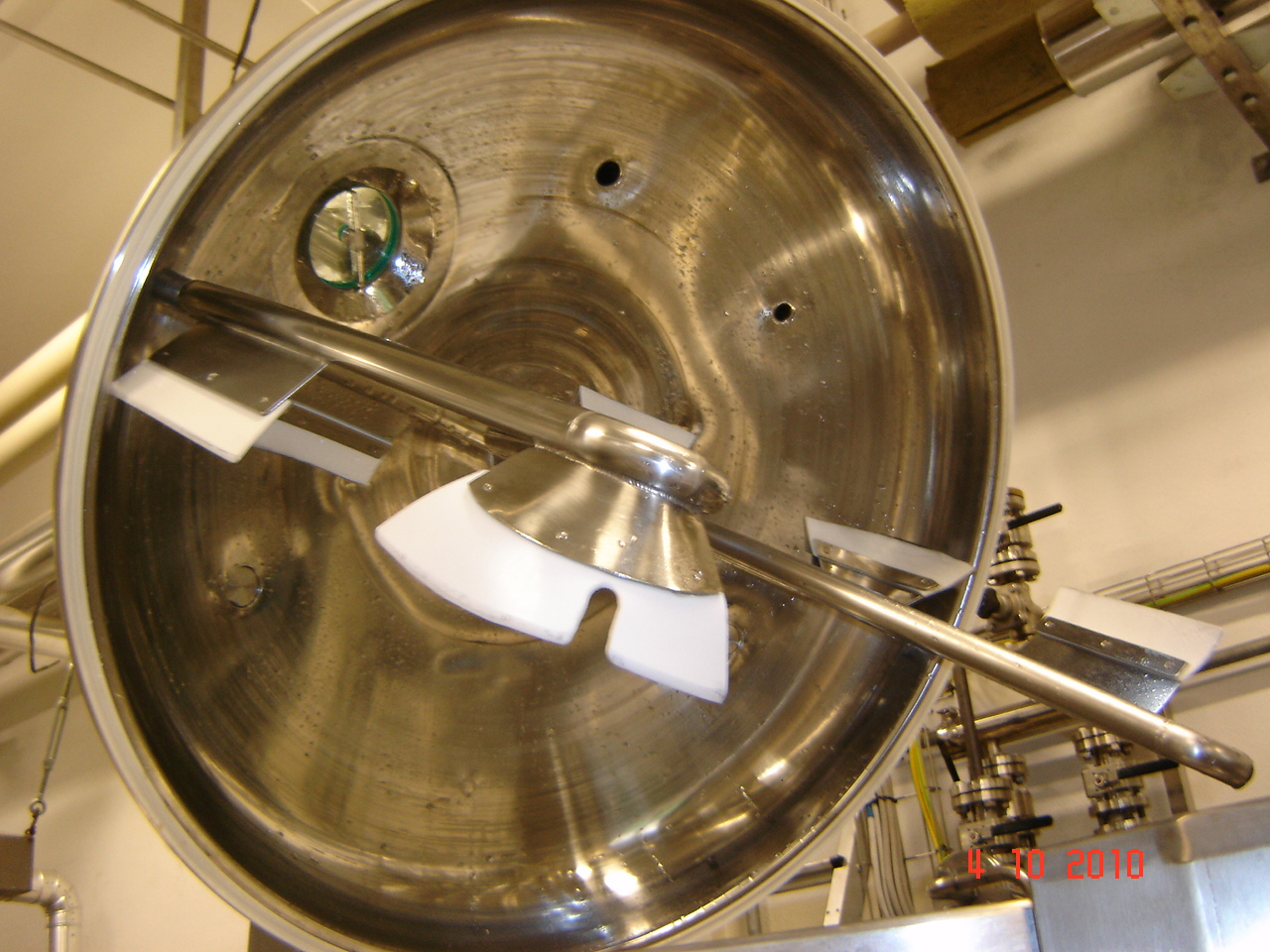

- Evaporators under vacuum with capacities from 15 to 2.000 kg complete with scraping blades, or with horizontal axis with rotating heated serpentine, or with vertical axis with the double bottom, ideal for canning industry. Laboratory concentration bull;

- Cookers from 300 to 600 liters with heated cavity, scraping blades both horizontal and vertical axis, and unloading both from the bottom and with tilting system for the preparation of sauces, creams and pests with the possibility of cooking ideal to maintain the integrity of both the taste and the color of the products;

- Cutters with capacities up to 250 liters, single, with a heated cavity (or cooled) and jacketed and vacuum system for cutting and / or cooking – concentration with low-temperature, of fruit and vegetables, sauces and pests;

- Construction of pressure tank, heat exchanger for chemical, petrolchemical and other industries.